Since 2006

Worm Drive

Hours

Monday – Friday

11am – 11pm

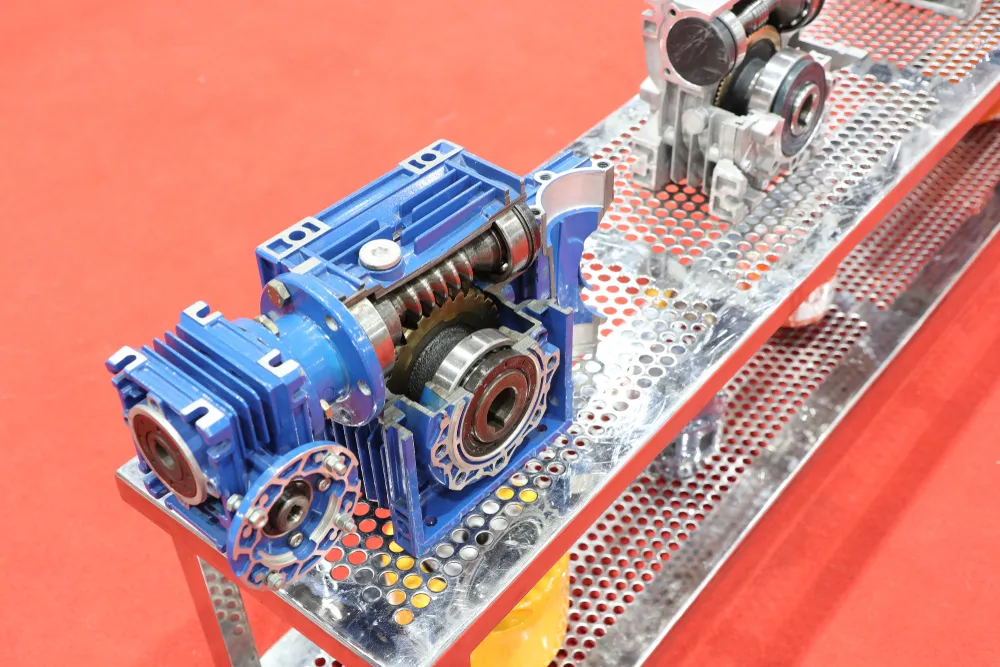

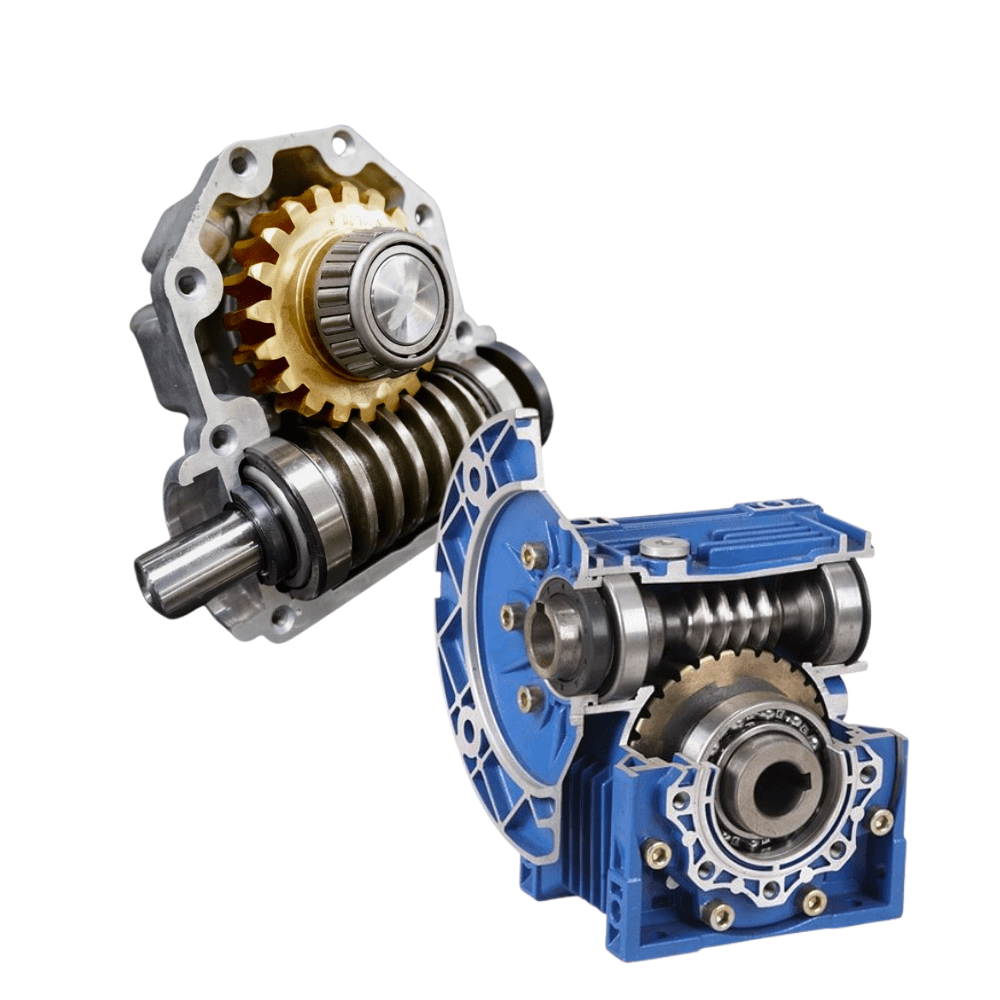

What Is Worm Drive

A worm drive is a type of gear arrangement commonly used in machinery and automotive applications. It consists of a worm gear and a worm wheel, which are also known as a worm screw and worm gear, respectively. The worm gear has a helical thread that meshes with the teeth on the worm wheel, which is perpendicular to the worm gear.

This design creates a high gear reduction ratio, which is why worm drives are often used in applications that require high torque output and low speed, such as in heavy-duty machinery and vehicles. However, worm drives are also less efficient than other types of gear arrangements, such as spur gears, due to the sliding friction that occurs between the worm gear and the worm wheel.

Features of Worm Gearbox

Worm gearboxes, also known as worm gear reducers or worm drives, possess several distinct features that make them suitable for specific applications. Here are some key features of worm gearboxes:

Smooth and Quiet Operation

Worm gearboxes typically operate with relatively low noise levels and produce smooth and steady motion, particularly when properly lubricated.

Versatile Mounting Options

Worm gearboxes can be mounted in various orientations, including horizontal, vertical, or angled positions, offering flexibility in installation.

Cost-effective

Worm gearboxes are often cost-effective compared to other types of gearboxes with similar torque capabilities.

Temperature Resistance

Worm gearboxes can handle a wide range of operating temperatures, making them suitable for applications in diverse environments.

Learn More

What Is Worm Drive

A worm drive is a type of gear arrangement commonly used in machinery and automotive applications. It consists of a worm gear and a worm wheel, which are also known as a worm screw and worm gear, respectively. The worm gear has a helical thread that meshes with the teeth on the worm wheel, which is perpendicular to the worm gear.

This design creates a high gear reduction ratio, which is why worm drives are often used in applications that require high torque output and low speed, such as in heavy-duty machinery and vehicles. However, worm drives are also less efficient than other types of gear arrangements, such as spur gears, due to the sliding friction that occurs between the worm gear and the worm wheel.

How Does a Worm Gear Reducer Work?

The worm gear has a helical thread that meshes with the teeth on the worm wheel. Because of the helical thread, each rotation of the worm gear causes the worm wheel to rotate by only a fraction of a full turn, which creates a high gear reduction ratio between the input and output shafts. The gear reduction ratio depends on the number of teeth on the worm wheel, the pitch of the worm gear, and the angle of the worm gear’s thread.

As a result of the high gear reduction ratio, the output shaft rotates at a much lower speed than the input shaft but with significantly increased torque output. This makes worm gear reducers ideal for applications that require high torque output and low speed, such as in heavy-duty machinery and vehicles.

It’s important to note that worm gear reducers are less efficient than other types of gear arrangements, such as spur gears, due to the sliding friction that occurs between the worm gear and the worm wheel. This sliding friction can cause wear and tear on the gear components over time and may result in some power loss as heat energy. Therefore, it’s essential to select the right type of reducer for the application and ensure proper lubrication to minimize wear and tear.

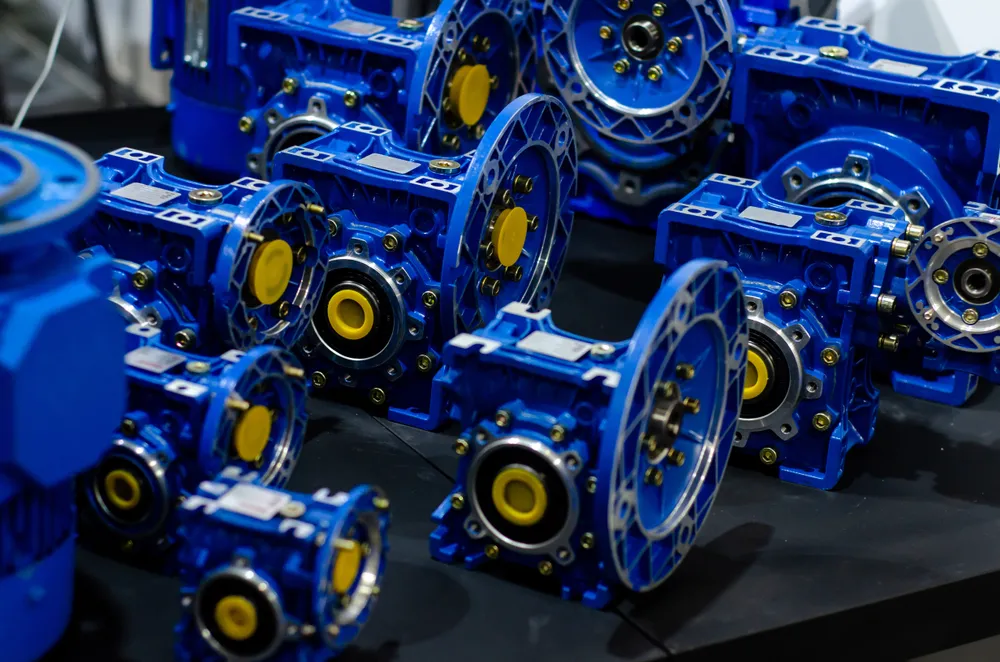

Worm Gearboxes for Sale

As a worm gearbox manufacturer, we will do our best to serve you. If you need customized products, or the products you need are not found on our website, or need a product catalog, don’t worry, more of our products are still being uploaded. You can email us directly, and we will reply to you within 24 hours!

Where Is a Worm Gearbox Used?

Worm gearboxes are used in a variety of applications that require high torque and low speed, such as in heavy-duty machinery and vehicles. Some specific applications where worm gearboxes are commonly used include:

Conveyor Systems

Worm gearboxes are used in conveyor systems to move heavy loads at a slow and controlled speed.

Heavy-duty Vehicles

Worm gearboxes are used in heavy-duty vehicles, such as trucks and buses, to provide the necessary torque for power transmission.

Material Handling Equipment

Worm gearboxes are used in material handling equipment, such as cranes and hoists, to lift and move heavy loads.

Industrial Equipment

Worm gearboxes are used in various industrial equipment, such as mixers, extruders, and shredders, to provide the required torque for the operation.

Agriculture Equipment

Worm gearboxes are used in agriculture equipment, such as tractors and harvesters, to provide the necessary torque for the farming operations.

Renewable Energy

Worm gearboxes are used in wind turbines and solar tracking systems to adjust the pitch of the blades and the position of the solar panels, respectively.

Our Mission

We sell you what you need, not what we need to sell.

Who We Are

Hangzhou EPT Transmission Co., Ltd. specializes in the production of various mechanical transmissions and hydraulic transmissions, such as:

Parallel shaft helical gear reducer, planetary gearbox, worm reducer, in-line helical gear reducer agricultural reducer, spiral bevel gear reducer, helical worm gear reducer, agricultural gearbox, tractor gearbox, automotive gearbox, pto drive Shafts, special reducers and related gear parts and other related products, sprockets, hydraulic systems, vacuum pumps, fluid couplings, racks, chains, timing pulleys, overdrive transmissions, V-belt pulleys, hydraulic cylinders, gear pumps, screws Air compressor, collar, low backlash worm reducer, etc.

In addition, we can produce customized transmissions, geared motors, electric motors and other hydraulic products according to customers’ drawings.

Due to our excellent product quality and after-sales service, we have exported our products to clients all over the world and won a good reputation.

We warmly welcome customers at home and abroad to contact us, negotiate business, exchange information, and cooperate with us.

We have more than 1500 workers and have CNC lathes and CNC machining centers.

Do You Need More Information on These Products?

Fill out the contact form or ask our technical department for a consultation